Material Overview of Nylon

What is Nylon (PA)?

Nylon is a synthetic plastic material popular for its toughness, low coefficient of friction, and resistance to abrasion and wear. It is one of the most widely engineered thermoplastics with applications including machining components, fabrics, and moving parts such as wheels and rollers.

Nylon offers exceptional mechanical performance, making it the preferred plastic for injection-molded engine components. It is also used to replace low-strength metals such as bronze, brass, and aluminum in engineering applications.

Why is Nylon Popular?

Many industries choose nylon because it is a cost-effective plastic with high functionality. Nylon polymers can be modified with a variety of additives to enhance certain features for targeted functions. Overall, this thermoplastic possesses a number of advantageous qualities that are utilized across a number of industries.

Outstanding Features:

- Highest wear-resistant thermoplastic available

- Low coefficient of friction

- High melting temperature

- Good chemical resistance

- Easy to machine

- Excellent cost-to-performance ratio

|

Temperature Range |

-20° to 210° F |

-40° to 230° F |

-20° to 200° F |

-20° to 200° F |

|

Tensile Strength |

13,000 psi |

13,000 psi |

11,000 psi |

11,000 psi |

|

Impact Strength |

0.6 ft. - lbs./in. |

0.6 ft. - lbs./in. |

1.1 ft. - lbs./in. |

0.3 ft. - lbs./in. |

|

Hardness |

Rockwell M85 |

Rockwell M88 |

Rockwell R110 |

Rockwell R115 |

|

Density |

0.041 lbs / cu. in. |

0.042 lbs / cu. in. |

0.042 lbs / cu. in. |

0.042 lbs / cu. in. |

|

Features |

Greater strength and stiffness compared to Nylon 6/12 |

Stronger glass reinforced material, more resistant to abrasion and wear |

MDS internal lubricant, more slippery and wear resistant |

More resistance to water and moisture compared to Nylon 6/12 |

Properties of Nylon

Nylon can be cast, extruded, and is also suitable for injection molding and 3D printing. Its high melting point makes it a great substitute for metals used in high-temperature applications. This is why it is often used for engine components in vehicles or machine parts like seals and gaskets.

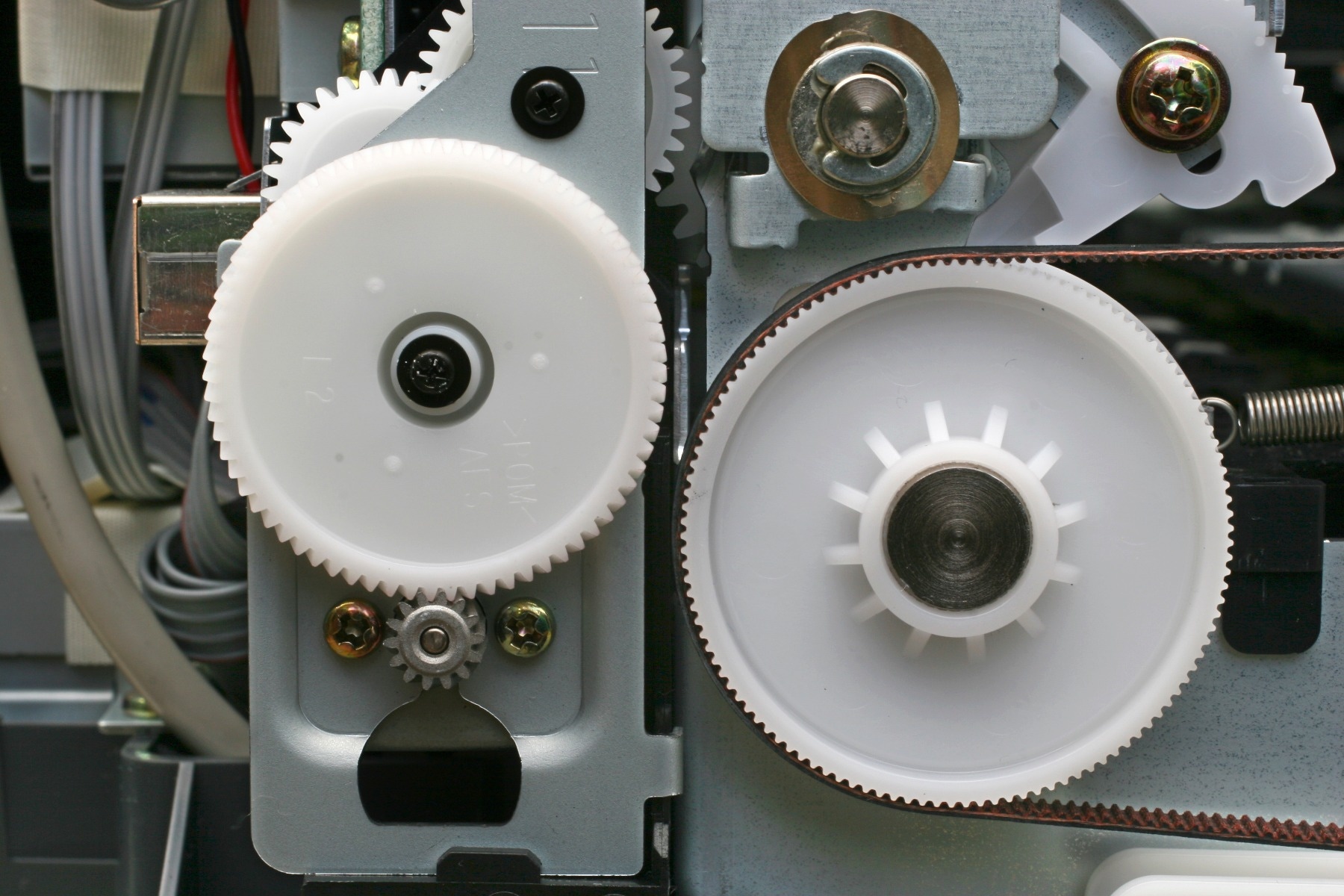

Nylon gears used to drive a machine belt

As a thermoplastic, nylon will become a liquid at its melting point, 428°F in this case. Once melted, it can be cooled and reheated again without significant degradation. This makes it a popular choice for injection molding.

Common Uses

- Moving parts: gears, bearings, bushings, wheels, and rollers

- Food processing machining components, films for packaging

- Fabric and fibers: textiles, flooring, rope, thread, parachutes, bristles

- Vehicle components: reinforcement for car tires, molded engine parts

- Industrial: seals, gaskets, wear pads

Nylon vs Acetal

Both nylon and acetal are versatile thermoplastics which make many of the same parts and products. They share properties including good chemical resistance, excellent resistance to wear, and a sharp melting point. So when is it the right time to use each plastic? Let's compare some of their characteristics against each other.

|

Nylon |

Acetal |

|

|

Advantages |

|

|

|

Disadvantages |

|

|

|

Better compatibility |

|

|

Something to consider is that there is a good chance the mechanical properties of nylon will change over time due to moisture. It is capable of absorbing up to 8% moisture by weight at saturation, compared to 0.8% for acetal.

While this may be a determining factor for applications requiring high levels of dimensional stability, filled nylon systems are available that absorb much less moisture.

Nylon and acetal are both heavily relied upon in the industrial world. Each offers a strong set of properties that can be utilized in many applications.

Contact Us

For more information or inquiries about nylon products, please contact us at 888-839-0681 or service@fixsupply.com.